Description of the Project:

The Owner: General Establishment of Syrian Railways (CFS), Tartous region.

The bridge had 3 spans, double T reinforced concrete girders, two-column piers, and massive abutments. The bridge was collided by heavy vehicle. 3 rebars were distorted, considerable amount of existing concrete were spalled, delaminated and lost the bond with the rebars. Fig (60).

My Role in the Project (in Detail):

1) I reviewed the inspection report very carefully to estimate the damaged area, and the consequences on the structural integrity and behavior of the superstructure. See fig. (61).

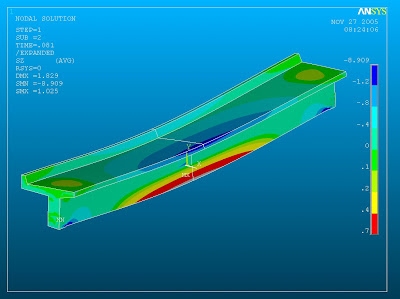

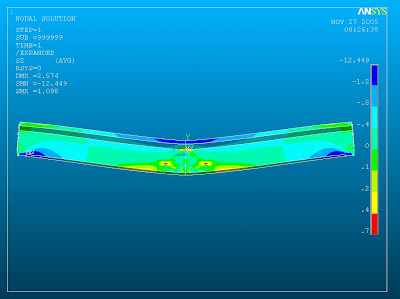

2) I conducted the structural evaluations in two methods: The 1st one was accomplished utilizing nonlinear finite element package (Ansys), fig. (62 and 63). The 2nd one (which additionally required by the auditor of the project) was frame element analysis using MIDAS Civil, fig. (64). The 1st method adopted to find the exact existing strength in the superstructure, the redistribution of the stresses after cracking, as well as the failure mode. The safety factor in the simple model for the deteriorated section was 0.45, while in the sophisticated model using Ansys was 0.92.

3) I negotiated with the client’s representatives and the auditor about the sound engineering judgment regarding the structural safety and the level of strengthening that would be required.

4) In order To find the proper strengthening, and restoration processes to the bridge, I recommended very urgent items, and they were: compensate the lost reinforcement, inject the cracks by epoxy III (808C ASTM’s classifications), and apply the shotcrete after careful surface preparations. Also, I submitted secondary items like ballast cleaning and compaction, ties (sleepers) replacements, wedges setting up, traffic barriers installation, handrail restoration, repair the corroded supports, joint sealing/replacing, and apply surface protection coatings.

The Owner: General Establishment of Syrian Railways (CFS), Tartous region.

The bridge had 3 spans, double T reinforced concrete girders, two-column piers, and massive abutments. The bridge was collided by heavy vehicle. 3 rebars were distorted, considerable amount of existing concrete were spalled, delaminated and lost the bond with the rebars. Fig (60).

My Role in the Project (in Detail):

1) I reviewed the inspection report very carefully to estimate the damaged area, and the consequences on the structural integrity and behavior of the superstructure. See fig. (61).

2) I conducted the structural evaluations in two methods: The 1st one was accomplished utilizing nonlinear finite element package (Ansys), fig. (62 and 63). The 2nd one (which additionally required by the auditor of the project) was frame element analysis using MIDAS Civil, fig. (64). The 1st method adopted to find the exact existing strength in the superstructure, the redistribution of the stresses after cracking, as well as the failure mode. The safety factor in the simple model for the deteriorated section was 0.45, while in the sophisticated model using Ansys was 0.92.

3) I negotiated with the client’s representatives and the auditor about the sound engineering judgment regarding the structural safety and the level of strengthening that would be required.

4) In order To find the proper strengthening, and restoration processes to the bridge, I recommended very urgent items, and they were: compensate the lost reinforcement, inject the cracks by epoxy III (808C ASTM’s classifications), and apply the shotcrete after careful surface preparations. Also, I submitted secondary items like ballast cleaning and compaction, ties (sleepers) replacements, wedges setting up, traffic barriers installation, handrail restoration, repair the corroded supports, joint sealing/replacing, and apply surface protection coatings.